VCSEL (vertical-cavity surface-emitting laser) has the advantages of low threshold, good stability, long service life, high modulation rate, high integration, small divergence angle, and low cost.

With the application of the 10 Gbit/s Ethernet standard and 10 Gbit/s fiber channel standard, the optical module using VCSEL has been vigorously promoted in storage area networks and optical fiber LAN.

At present, in the field of 10 Gbit/s short-range transmissions, the emission part of the 10GBASE-SR SFP+ optical module adopts plastic encapsulated 850 nm VCSEL TOSA (optical emission device).

The change in temperature characteristics has a great negative impact on the performance of high-speed optical modules in the full temperature range (- 40 ~ 85 ℃), which will lead to a decline in the transmission quality of optical communication systems.

Therefore, it is necessary to design the temperature control part of the high-speed optical module. In this paper, the PI (power current) characteristics of QSFPTEK’s 10 Gbit/s 850nm VCSEL TOSA at high and low temperatures are studied.

The module-level temperature compensation is carried out by means of sampling, calculation, and piecewise compensation, which ensures the stability of the emitted optical power and EXT (EXTinction ratio) of the high-speed optical module in the full temperature range, and is verified by experiments.

Temperature Compensation Design of Module Transmitting Part

A high-speed SFP+ optical module is the core component of optical communication systems. Keeping the output optical power stable in the full temperature range is the focus of the transmission part of the high-speed SFP+ optical module.

The design temperature of the SFP+ SR module based on plastic encapsulated 10 Gbit/s 850nm VCSEL is – 40 ~ 85 ℃. Without an ATC circuit, the change of optical module performance index parameter value caused by laser temperature characteristics may exceed the allowable range of system design, resulting in abnormal communication signals.

Therefore, when designing the module circuit, the temperature control system must be used to monitor and compensate for it in real-time, so as to ensure the stability of EXT and the luminous power of the optical module, and the normal operation of the optical communication system.

Temperature Characteristics of Vcsel TOSA

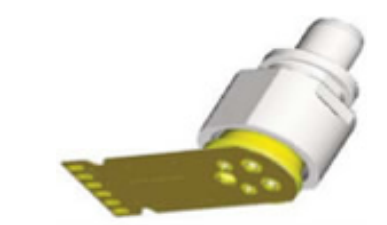

The plastic encapsulated 10GBASE-SR SFP+ 850nm VCSEL TOSA is encapsulated by 10Gbit / s 850nm VCSEL TO (coaxial packaging), nonball cap integrated plastic encapsulated adapter, two-piece plastic encapsulated flexible circuit board, and coaxial form, as shown in the figure below.

塑封 8 5 0 nm VCSEL TOSA 外形图

The plastic packaging material used is PEI (polyetherimide), which is commonly used in the industry. The manufacturing process is to use UV adhesive for one-time curing, and then use thermal curing adhesive to strengthen the curing for viscous coupling.

TO high-frequency design combined with flexible circuit board design can meet the requirements of high-speed SFP+. The temperature characteristics of the 850nm VCSEL chip and the plastic packaging method adopted by 850nm VCSEL TOSA make the 850nm VCSEL TOSA show unique temperature characteristics.

Temperature Compensation Technology of Module

The common EXT temperature compensation schemes for high-speed SFP+ modules include the open-loop compensation method and the closed-loop compensation method.

The 10 Gbit/s SFP+ SR short-range optical module designed by QSFPTEK uses the closed-loop compensation method: APC + thermistor compensates the modulation current for temperature monitoring and compensation.

By adjusting the thermistor outside the IC chip, reasonably setting the relevant resistance value, and compensating the modulation current, the module EXT is basically stable when the ambient temperature changes.

The temperature control system is located in the control circuit part of the 10 Gbit/s SFP+ SR module. When the transmitting part of the optical module works, the temperature acquisition unit samples the current working temperature information of the optical module laser and reports it to the single-chip microcomputer compensation control unit.

The compensation control unit corrects the tracking error of the APC laser according to the temperature and compensation coefficient, establishes an appropriate bias current, ensures the stability of the transmitted optical power, and obtains the current bias current of the laser at the same time.

According to the calculation coefficient of the modulation current, the required modulation current value at each temperature is calculated in real-time, and the laser driving circuit is controlled to provide the appropriate modulation current for the laser and ensure the stability of the optical module EXT.

Power compensation and modulation current calculation are realized by a single chip microcomputer, which controls the work and connection of each hardware circuit.

The working temperature of the 10 Gbit/s SFP+ SR module is the industrial temperature. Calculate the K value of each laser at – 40 ℃ / 85 ℃. Remove the gross error and obtain the average K value, which is the compensation coefficient.

Since the threshold current of 850nm, VCSEL increases with the increase of temperature in the environment above 25 ℃ and increases with the decrease of temperature in the environment below 25 ℃.

The corresponding compensation coefficient adopts a signed number to correct the tracking error from the positive and negative directions, and the power compensation control unit compensates for the tracking error in sections.

The temperature compensation system establishes appropriate bias current and modulation current for the current, power, and tracking error of the laser at different temperatures, reduces the start-stop control delay of the laser, eliminates relaxation oscillation, and maintains stable optical power and EXT; For the problems of sensitivity and signal alarm under weak signal, compensation and optimization are carried out, so as to improve the performance of high-speed and short-distance module in the industrial temperature range.

10G SFP+ SR Module Test Results

1. Transmitted Optical Power before and after Temperature Compensation

Five 10 Gbit/s SFP+ short-range optical modules were tested before and after temperature compensation. The temperature compensation control unit takes 25 ℃ as the segment point to compensate for the tracking error. The negative coefficient is adopted for – 40 ~ 25 ℃ and the positive coefficient is adopted for 25 ~ 85 ℃.

The test results show that after using the temperature compensation system, the change of optical power of 10 Gbit/s SFP+ short-range optical module in the working temperature range of – 40 ~ 85 ℃ is reduced from about 1.4 DB to about 0.5 dB, which improves the optical power consistency of 10 Gbit/s SFP+ optical module in the whole temperature range and is more conducive to the transmission of the optical signal.

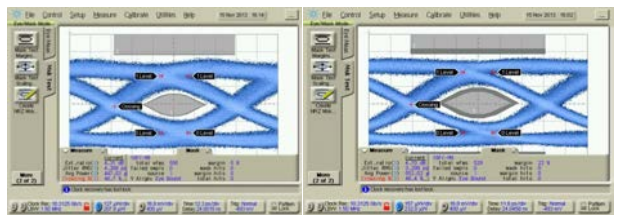

2. Emission Eye Diagram before and after Temperature Compensation

We compared the emission eye diagram of the emission part of the 10 Gbit/s SFP+ short-range optical separation module under high temperature and before and after using the temperature compensation method designed in this paper, as shown in the figure below.

It can be seen from the figure that when using the conventional temperature compensation method, although the eye diagram meets the requirements, it has shortcomings and still has room for improvement;

Compared with the former, the temperature compensation method designed in this paper improves the noise, overshoot, and jitter caused by high temperature, and improves the eye image quality and EXT stability.

Comparison of emission eye patterns before and after temperature compensation method designed by QSFPTEK

Read Also: