Injection molding can also be called Moulding; it is a manufacturing process where new and innovative things can be produced by injecting liquid or pliable materials inside a mold or mold. If you have just entered the molding world, you might be looking for ways to build new things through the molding process. Then you can relax and sit back as you have come to the right place. Here we have provided and explained some ways to achieve undercut Success in Molded Parts.

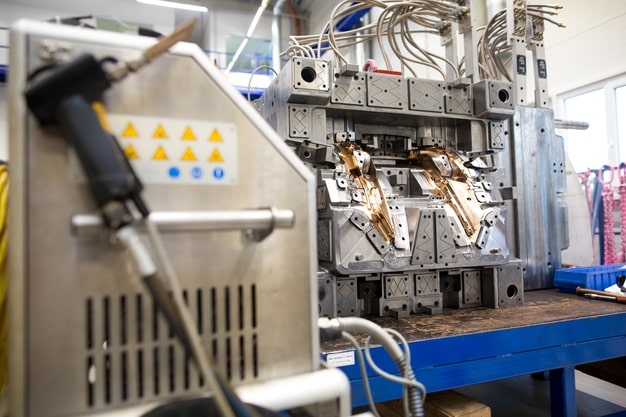

Let me first tell you that Injection Molding Undercuts are used to define the protrusions, cavities, or recessed areas of a part of an object. Undercut on Molded parts are the facility that protects the part from being directly discharged from a molding machine. The injection process is done on a special machine that has three parts: the injection unit, the mold itself, and the clamp. To create a perfect shape, everything needs to be placed in the right position to take the perfect appealing shape and require a high amount of expertise. Follow the below suggestions to achieve undercut success in Molded Parts.

Hack#1- Know When Undercut is important in Injection molding

It is always important to know if your parts need Undercut or not. Undercuts are beneficial to shape up and down twine, holes for buttons, or can be used in various medical devices to fasten any attribute. Sinking and Warping is also a common thing used by the Undercuts. Its main motive is to remove a particular section from an object to prevent defects.

Hack #2- Parting Of Lines

You can move the parting lines and adjust the draft angles according to your wish to insert the undercut. In this process, you can prevent parts from getting damaged. As everything has limitations, this also has its limitation, based on geometry, material flow, and other features of the object or part.

Hack#3- Sides of Actions

The side of actions is highly recommendable to deal with the cylindrical parts. You know that mold is split horizontally along the part, so you can try the perpendicular side actions in the cylindrical objects. Once the adhesive is shot into the mold and starts to cool, this is the time when the side-action slides on an angled pin can be executed until it is clear from the undercut. You have to give some time allowing it to be freely discharged.

Hack#4- Siding Shutoffs

Sliding Shut Offs are a special form of technology that is used to create clip and hook style constituents. These are created to lock together in two halves of a mold. During mold operation, these mechanisms are used to seal things together; it creates a shutting off factor that is certain in areas of the part to create complex features, such as holes.

Hack#5- Bump Offs

If your object has a mild undercut, then you can make a distinguished interjection in the mold. This interjection will give an extra latch into the mold. Plastics are beyond the ejection process as the plastic succinctly stretches over the insert but latterly resumes its desired form as it was before.

Hack#6- Hands of loaded inserts

Hand-loaded is when a machine is inserted into the mold to prevent molten plastic from flowing into other areas. Plastic in liquid can flow here and there, ruining everything, so this process can be applied. Beyond the out-and-out prospectus of the cycle, the inserts are pouring out with the part. You will need an operator to pick them off the part for further use.

Hack#7- Part design or secondary options

Creating blueprints for your part is important as without those, it will be impossible for you to achieve the desired form and shape. When an expert injects the mold, it will be easily evaluated into a part’s manufacturability. Implementing design features to circumvent the apprehensions of any unavoidable undercuts needs proper expertise in the part. So working with a professional, experienced manufacturer is highly important.

Conclusion

Working with highly experienced professionals will help you build the best design and help you take the future steps of the molding process. The whole process can be highly dangerous if not handled with care.

Read Also: